By implementing technologies such as the Internet of Things (IoT), big data analytics, artificial intelligence (AI), and machine learning, we enable the digitalization, networking, and intelligence of production lines in factories. This transformation aims to improve production efficiency, reduce costs, and deliver higher-quality products. Additionally, it ensures safe operations within high-tech manufacturing environments.

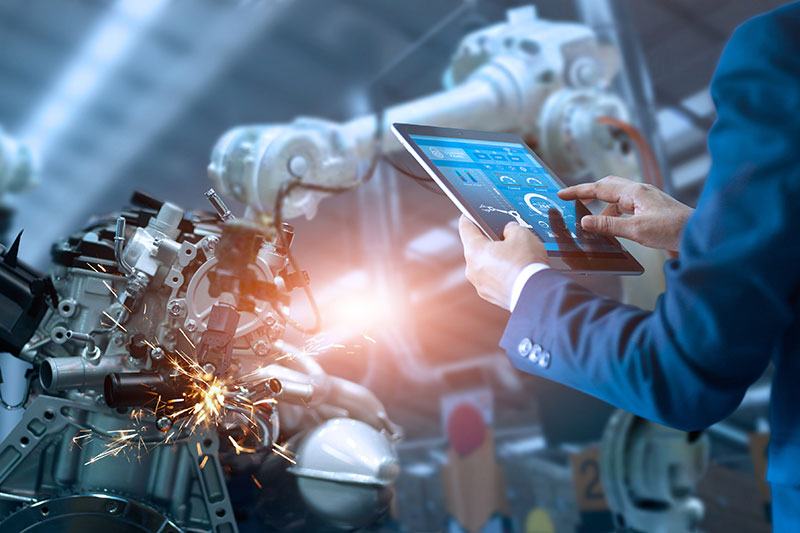

IoT integration allows for real-time monitoring and control of machines and equipment, enabling predictive maintenance and optimizing production processes. Data analytics and AI algorithms analyze vast amounts of data collected from sensors, machines, and production systems, providing valuable insights for process optimization, quality control, and predictive maintenance.

Machine learning algorithms can be applied to improve product quality by detecting defects or anomalies in real-time, allowing for immediate corrective actions. Robotics and automation technologies further enhance efficiency by performing repetitive tasks with precision and speed.

Additionally, the implementation of intelligent safety systems, such as machine vision and advanced robotics, ensures a safe working environment for employees by detecting potential hazards and reducing the risk of accidents. Overall, these technologies empower factories to achieve higher productivity, lower costs, improved product quality, and enhanced safety in their manufacturing processes.(Automated Production、Real-time Data Analysis、Collaborative Mechanisms、Energy Efficiency)

IoT integration allows for real-time monitoring and control of machines and equipment, enabling predictive maintenance and optimizing production processes. Data analytics and AI algorithms analyze vast amounts of data collected from sensors, machines, and production systems, providing valuable insights for process optimization, quality control, and predictive maintenance.

Machine learning algorithms can be applied to improve product quality by detecting defects or anomalies in real-time, allowing for immediate corrective actions. Robotics and automation technologies further enhance efficiency by performing repetitive tasks with precision and speed.

Additionally, the implementation of intelligent safety systems, such as machine vision and advanced robotics, ensures a safe working environment for employees by detecting potential hazards and reducing the risk of accidents. Overall, these technologies empower factories to achieve higher productivity, lower costs, improved product quality, and enhanced safety in their manufacturing processes.(Automated Production、Real-time Data Analysis、Collaborative Mechanisms、Energy Efficiency)